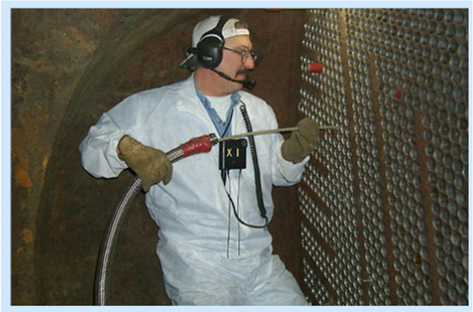

In service detection of heat exchange pipe and condenser in power station can remove interference signal of support plate to remove false and real, and detect the signal of cracks caused by support plate injury.

Intelligent full digital multi frequency eddy current detector is a new generation of eddy current nondestructive testing equipment. It adopts the most advanced digital electronic technology, multi frequency eddy current technology and microprocessor technology, and can effectively detect the inner and outer wall defects of ferromagnetic and non ferromagnetic metal pipes in real time. Intelligent full digital multi frequency eddy current detector is not only a complete eddy current testing system, but also can be compared with conventional multi frequency eddy current testing system Frequency, multi-channel ordinary eddy current testing system into a high-performance, multi-purpose, intelligent eddy current testing equipment.

Because of four relatively independent test channels, two absolute and two differential eddy current signals can be obtained at the same time. The instrument can be switched into two single frequency eddy current detectors by soft switch, and two probes can be connected at the same time. The instrument has a variable frequency range of 50 Hz to 10 MHz, and it has a very high amplification factor and strong anti-interference ability to the weak signal of eddy current testing. In the pipeline inspection, the inner through probe can be used to detect the cracks, pits, corrosion, thinning and internal defects on the inner and outer surface of the pipe through the pipeline at one time. It has the advantages of automatic detection, digital display, high sensitivity and stable performance under the control of computer. Therefore, 24et is especially suitable for flaw detection and wall thickness measurement of copper, titanium, aluminum, zirconium and other metal parts in service in nuclear power, electric power, petrochemical, aerospace, aviation and other departments, as well as flaw detection, analysis and evaluation of various ferromagnetic pipelines. For example: pre service and in-service inspection of boiler tubes, heat exchanger tube bundles, underground pipelines and cast iron pipes.